A UK based company is celebrating the arrival of new lightweight composite scaffold tubes set to change the way the industry utilises its materials. Scaffmag has been taking a closer look at the potential success of both lightweight tubing and brilliantly designed toe-boards clips.

Life is good when materials are easier to transport, handle and far less likely to lead to personal injury issues. It’s a goal the whole of the scaffolding industry is striving toward as we move deeper into the 21st century.

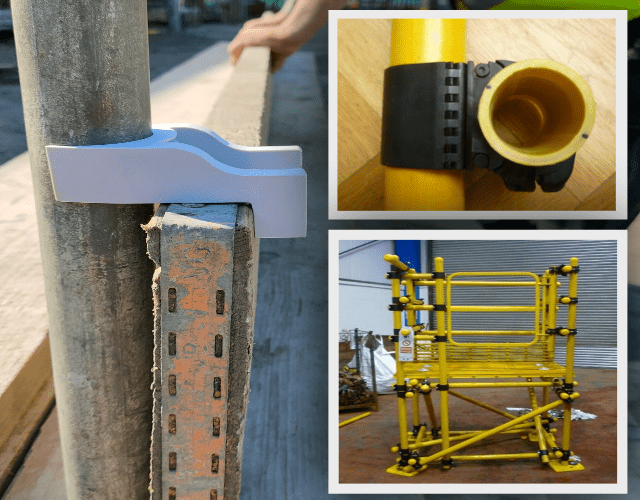

Thanks to the bods at Kapiti Engineering Ltd and Forefront Scaffolding Hire and Sales, a new form of tube is set to be snapped up by site professionals across Britain and beyond.

While the external diameter of com-tube is the same as conventional steel or aluminium scaffold tubes it has several other attractive features. Firstly, the resilience of the composite materials comprising the com-tube makes them resistant to corrosion even in hostile chemical environments.

What’s more, they are ideal for applications in both onshore and offshore marine locations. In fact, com-tube is ideal for operations in the vicinity of high voltage electrical works such as power stations, transmission lines and railways.

Due to their non-sparking properties com-tube provides an ideal solution when operating around potentially combustive environments such as chemical plants, and oil and gas facilities.

It’s important to note this innovative tubing is made from an advanced composite of resilient thermoset resin binding both longitudinal and spirally wound reinforcing fibres. This means it’s stronger in bending than traditional steel scaffolding tubes.

Toe Board Clip

If you thought one superb creation would suffice however, how about a versatile toe board clip designed to allow toe-boards to be secured against adjacent standards without the need for tightening bolts? Once again industry experience has been put to good use. As a result, the new com-clip has emerged made from a material that will never corrode.

Now, toe boards can be attached to the adjacent standards with a reasonable manual force. Once attached to the tube they should remain in position requiring a small force to manually slide them into place over the board. when positioned over an edge toe-board the locking arms should protrude far enough to allow a second end toe-board to be secured between the arms. Correctly positioned they certainly won’t be a safety hazard in any way, and in carrying a low weight the construction task is made even easier.

There is currently no specified regulatory requirement for the strength of toe-board clamps. “For toe boards, the horizontal point load is 0.150kN.” This relates to the strength of the toe board itself to an outwardly directed force from operations on the platform. These outwardly directed forces on the boards would be resisted by the toe board bearing against the standards against which they are attached meaning com-clip® toe board Clips are more than adequate. NASC TG 20 has a similar requirement to BS EN 12811-1.

Looking even closer it’s also necessary for the clip to be able to resist an inwardly directed wind force of between 0.06 and 0.08kN (6 and 8kgf). Tests have demonstrated the com-clip toe board Clips have a pull-off capacity of 0.075kN (7.5kgf).