How Much Weight Can Scaffolding Hold? ⚖️

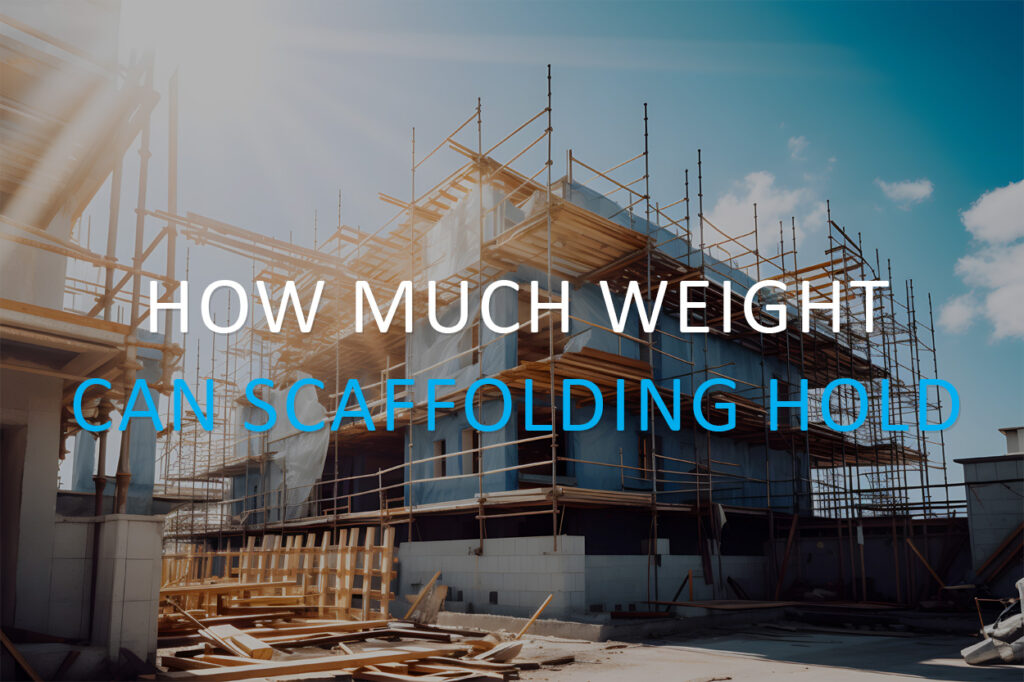

Scaffolding is an essential part of construction, maintenance, and renovation projects, providing a stable platform for workers to operate at height. However, one of the most critical aspects of scaffolding safety is its load capacity – the maximum weight it can support without risk of collapse. Overloading scaffolding can lead to serious accidents, making it vital for construction professionals, site managers, and property owners to understand weight limits and how they are determined.

At Silvercrest Scaffolding, we prioritise safety above all else, ensuring that every scaffold structure we erect meets strict safety regulations and industry standards. In this guide, we’ll explore the factors that determine scaffolding load capacity, the different classifications of weight limits, and best practices to ensure scaffolding remains safe and stable throughout a project.

What Determines Scaffolding Load Capacity?

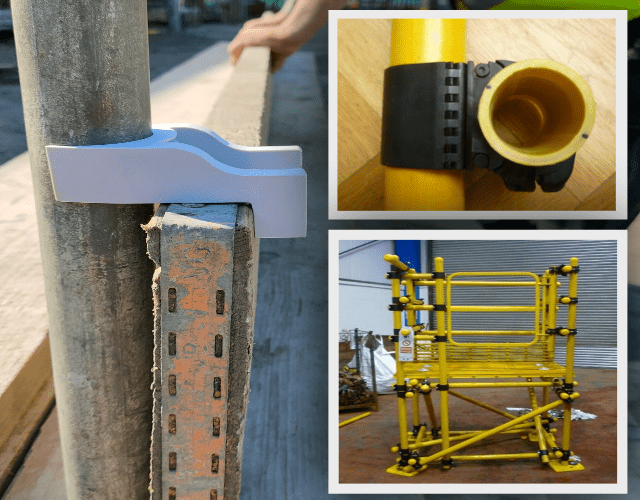

Scaffolding is designed to support both workers and materials, but its ability to bear weight depends on various factors. The design and structure of the scaffolding play a key role, with different systems offering varying levels of strength. Traditional tube-and-fitting scaffolding, for example, allows for custom configurations that can be adjusted to support heavier loads. In contrast, system scaffolding, such as Kwikstage or Cuplock, offers a more rigid, modular setup with pre-determined weight limits.

The materials used in scaffolding construction also significantly impact its load-bearing capacity. High-quality steel or aluminium components provide superior strength, while wooden scaffold boards must be carefully inspected to ensure they meet industry standards. The stability of the scaffold’s foundation is another crucial factor. If scaffolding is erected on uneven or weak ground, its ability to support weight is compromised, increasing the risk of collapse.

Bracing and tying the scaffold structure to a building further enhances its strength and weight capacity. Properly positioned braces help distribute weight evenly, while secure ties prevent excessive movement or instability. The spacing of vertical supports, known as standards, also affects load capacity. Closer spacing increases the scaffold’s ability to bear weight, whereas wider spacing reduces overall strength.

Understanding Scaffolding Load Classifications

Scaffolding in the UK is classified based on its intended use and weight-bearing capacity. These classifications help determine the type of scaffold required for different projects.

Light-duty scaffolding is typically used for domestic scaffolding projects such as painting, inspections, and minor repairs. This type of scaffolding can support a single worker with minimal tools and materials.

Medium-duty scaffolding is suitable for general construction work, including bricklaying, commercial work and electrical installations. It can accommodate multiple workers and moderate amounts of materials. This classification is commonly used in both domestic and commercial projects.

Heavy-duty scaffolding is designed for major construction and industrial work, supporting structural repairs, heavy masonry work, and projects that require the storage of large quantities of materials on the scaffold itself.

Special-duty scaffolding must be specifically designed to meet the needs of high-load projects, such as stone masonry, demolition work, or high-rise construction. Special-duty scaffolding requires structural engineering approval to ensure its safety and stability.

How to Ensure Scaffolding is Used Safely

Ensuring that scaffolding is not overloaded is a fundamental aspect of site safety. Before starting work, calculate the total weight to be placed on the structure, including workers, tools, and building materials. If the estimated load exceeds the scaffold’s rated capacity, adjustments must be made, such as reinforcing the structure or reducing the applied load.

Regular inspections are essential to maintaining scaffolding safety. Wear and tear, weather conditions, and prolonged use can weaken scaffolding components, reducing their ability to support heavy loads. Loose fittings, damaged boards, or excessive bending in support structures should be addressed immediately to prevent potential hazards.

Another key aspect of scaffolding safety is the even distribution of weight. Materials and equipment should be distributed across the platform rather than concentrated in a single area, which could cause an imbalance and a potential structural failure. Additionally, all workers using the scaffold should be adequately trained in load capacity limits and best practices to avoid accidental overloading.

Finally, working with experienced scaffolding professionals ensures that all structures are erected, maintained, and dismantled in accordance with British safety standards. At Silvercrest Scaffolding, our team is fully CITB-trained, and our materials conform to regulations, guaranteeing that every scaffold we provide is built to the highest safety standards.

Make the Right Decision: Contact Silvercrest Scaffolding!

Our team is on hand to provide immediate assistance, ensuring your site remains safe, accessible, and fully compliant.

Our rapid response service ensures that we can mobilise quickly to handle urgent situations, whether it’s an unexpected structural issue, emergency repairs, or access for inspection work. We have a highly skilled team, fully trained in the latest scaffolding techniques, and we provide tailored solutions to suit each project’s unique needs.

When time is critical, trust Silvercrest Scaffolding to deliver rapid, professional, and safe scaffolding solutions.

Got a project in the pipeline?

To discuss your upcoming projects please do get in touch

Office Tel: 01702 555 999

Website: www.silvercrestscaffolding.co.uk

Office Email: [email protected]

Technical/tenders: [email protected]